REDUCEST: THE BEST REDUCER EVER

BEYOND SPEED REDUCING

NEXT GENERATION REDUCER

Here is an innovative mechanism, a speed reducer or speed increaser, named "EXTREME" (EXtreme Transmission Ratio Efficient MEchanism) for the convenience of this presentation, which refers to a NON FRICTION BASED MECHANISM that transmits power with a VERY HIGH TRANSMISSION RATIO, inserting ONE only additional moving part between its input and its output, while its patent application has been published with the publication number: WO/2021/165707, receiving already an excellent Search Report and Written Opinion as well as a US Granted Patent.

Among a plenty of applications of this mechanism, a very important one is on a promising REDUCER.

MORE FOR THE EXTREME MECHANISM AT GREEN ENGINE PROJECT

MORE FOR THE EXTREME MECHANISM AT WIPO

So, here is an interesting proposal for a speed reducing or speed increasing mechanism.

It is the simplest ever solution for such a problem, since

- it has ONE ONLY MOVING PART between its input and output,

- it is NOT FRICTION BASED, while

- it is also very compact and lightweight, having its input and output in a coaxial arrangement, as well,

- and very simple in construction, operation and maintenance,

- having the greatest possible efficiency.

It is not just a breakthrough: moreover is the "simplest ever solution" in the strict mathematical sense.

Besides these, it is really new and innovative as it is already proved that there was no any other similar proposal until the 20th of February 2020:

there are already excellent Search Reports from WIPO (WO/2021/165707) and USPTO, where there is already a Granted Patent: US11940034B2.

It is obvious that it has no competitors in the field of speed reducers, easily achieving simple transmission ratios such as 100:1, or tremendous ones, even greater than 1,000,000:1.

It is the simplest ever solution for such a problem, since

- it has ONE ONLY MOVING PART between its input and output,

- it is NOT FRICTION BASED, while

- it is also very compact and lightweight, having its input and output in a coaxial arrangement, as well,

- and very simple in construction, operation and maintenance,

- having the greatest possible efficiency.

It is not just a breakthrough: moreover is the "simplest ever solution" in the strict mathematical sense.

Besides these, it is really new and innovative as it is already proved that there was no any other similar proposal until the 20th of February 2020:

there are already excellent Search Reports from WIPO (WO/2021/165707) and USPTO, where there is already a Granted Patent: US11940034B2.

It is obvious that it has no competitors in the field of speed reducers, easily achieving simple transmission ratios such as 100:1, or tremendous ones, even greater than 1,000,000:1.

REDUCEST project

We can vision, at last, transmission ratios such as 1,000,000:1 or even greater.

So, when "reducer" means the currently in use such mechanism, doing a slight abuse of the English grammar, "REDUCEST" is the name of the mechanism for the same purpose, in the superlative degree, as it is the top one without a single competitor.

Now, a version for a 6,400:1 transmission ratio is under development in close collaboration with the National Technical University of Athens (Laboratory of Machine Design & Dynamics), and possibly this version will be chosen to drive the rock drill of the next mission to Mars.

So, when "reducer" means the currently in use such mechanism, doing a slight abuse of the English grammar, "REDUCEST" is the name of the mechanism for the same purpose, in the superlative degree, as it is the top one without a single competitor.

Now, a version for a 6,400:1 transmission ratio is under development in close collaboration with the National Technical University of Athens (Laboratory of Machine Design & Dynamics), and possibly this version will be chosen to drive the rock drill of the next mission to Mars.

EXTREME: A Technical and Strategic Profile

Technical Principles and Advantages

Technical Principles and Advantages

The EXTREME represents a fundamental departure from conventional gear systems.

Its core technical principle, as described in the patent application WO/2021/165707, is the hybridization of the differential winch and the planetary mechanism.

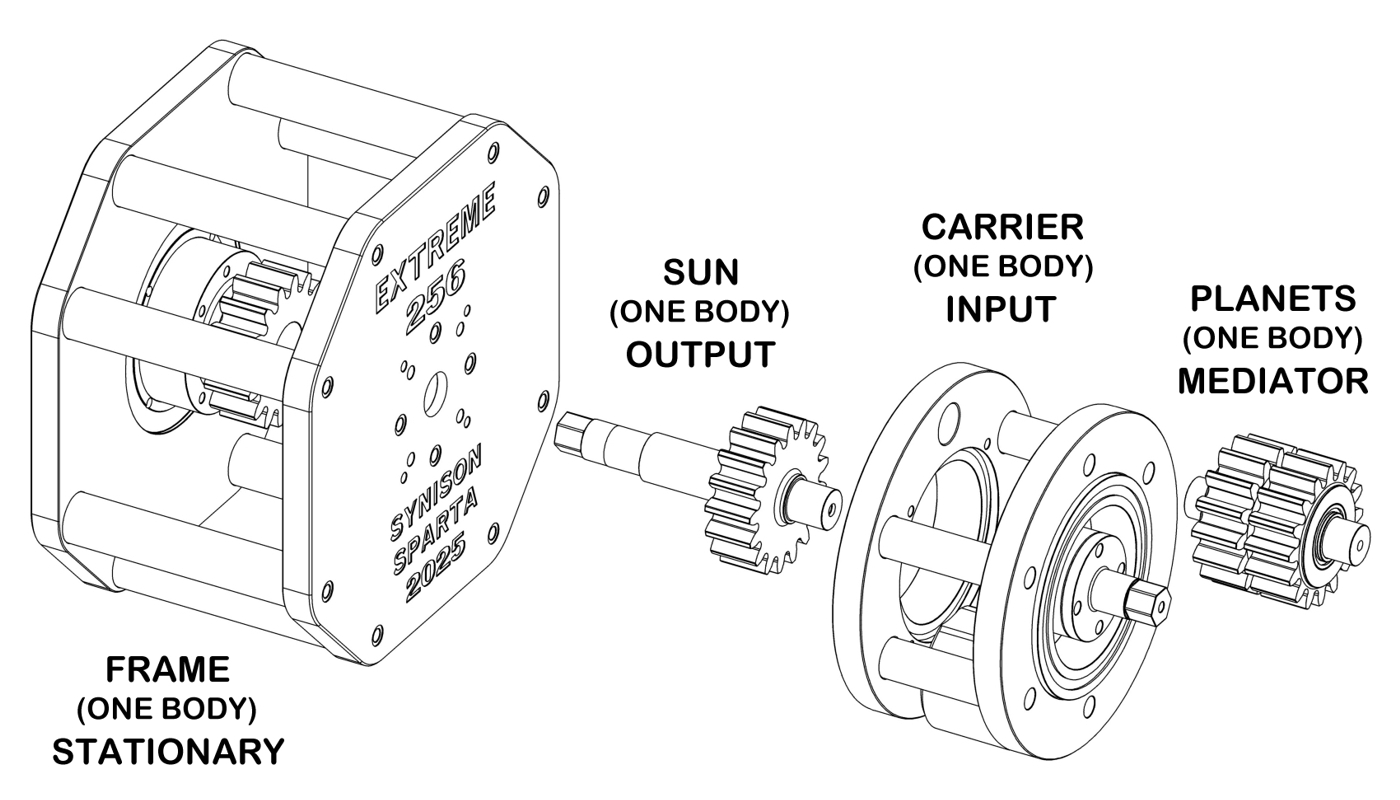

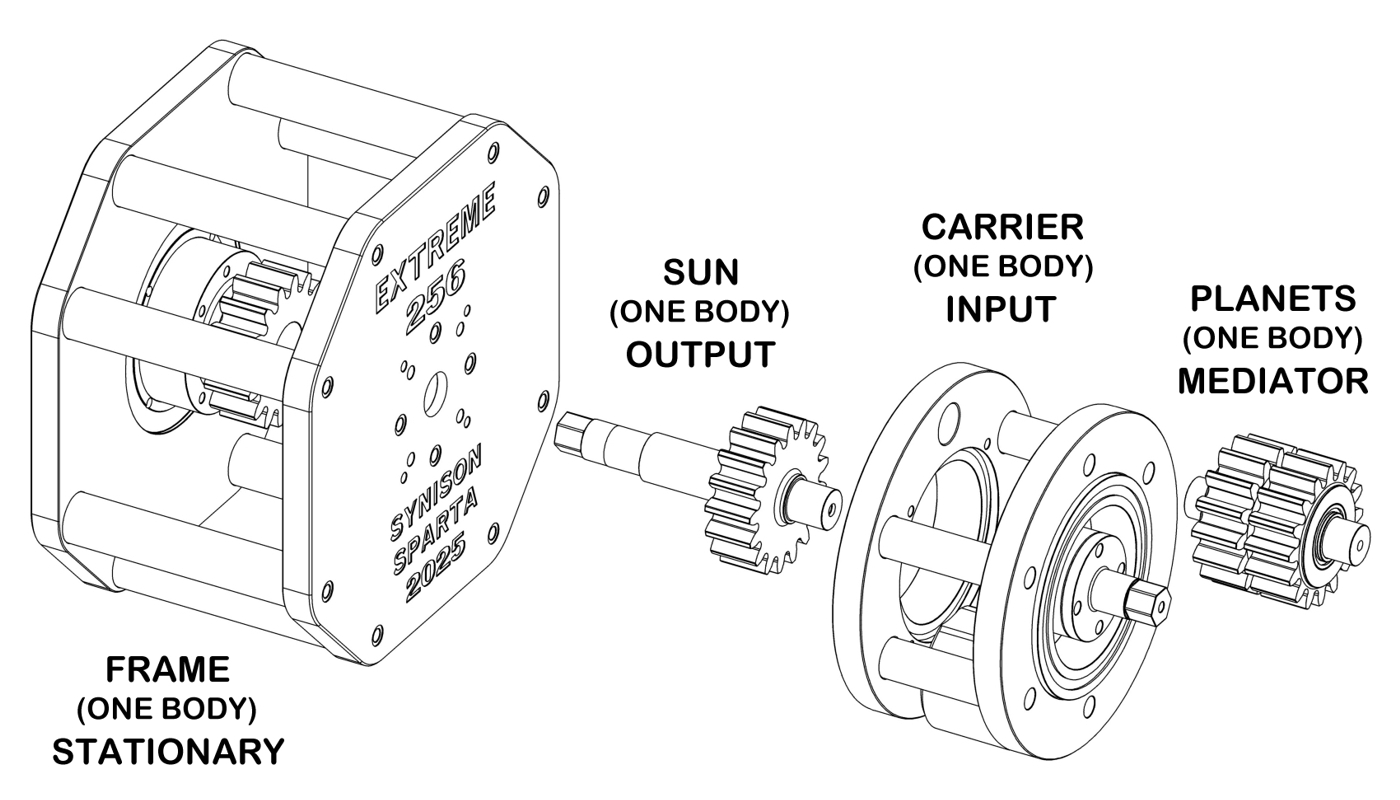

This innovative design results in an extremely high transmission ratio while utilizing a single only moving part between its input and output (drawing below: input/carrier, output/sun and mediator/planets).

This simplicity is a direct result of its revolutionary design, which challenges three established principles, or "dogmas," of mechanical engineering.

First, unlike conventional planetary mechanisms that rely on internal gears, the EXTREME uses only external gears, a configuration found to be more effective for achieving high transmission ratios.

Second, the design dispenses with the requirement that all gears must share the same gear module, allowing the use of different gear modules for different gear branches, one of which may be non standardized!

This provides a wider range of options for the number of teeth, enabling greater design flexibility and ratio optimization.

Third, the mechanism avoids the conventional 1:1 partial ratio in the one branch, instead setting a competitive value for the second branch that contributes to an even higher transmission ratio.

This approach is described as being "truly revolutionary" for its effect on performance.

The combination of these principles yields a mechanism with numerous strategic advantages.

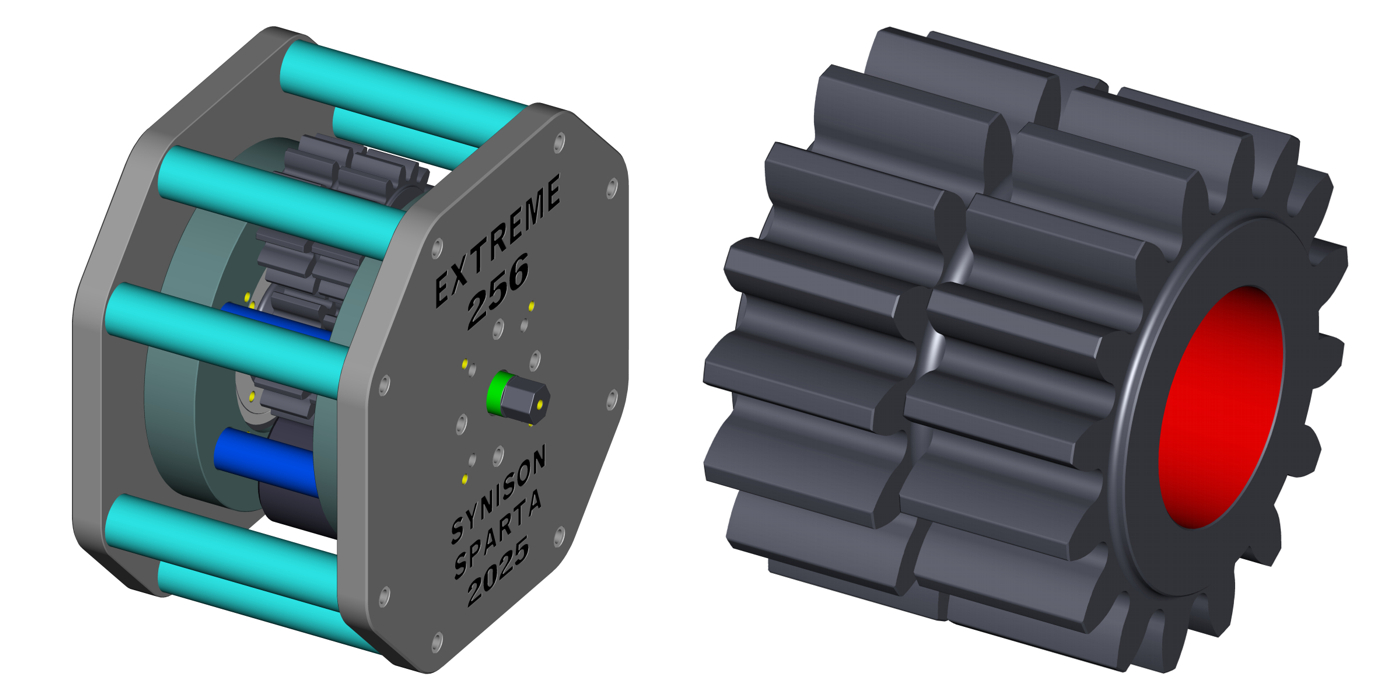

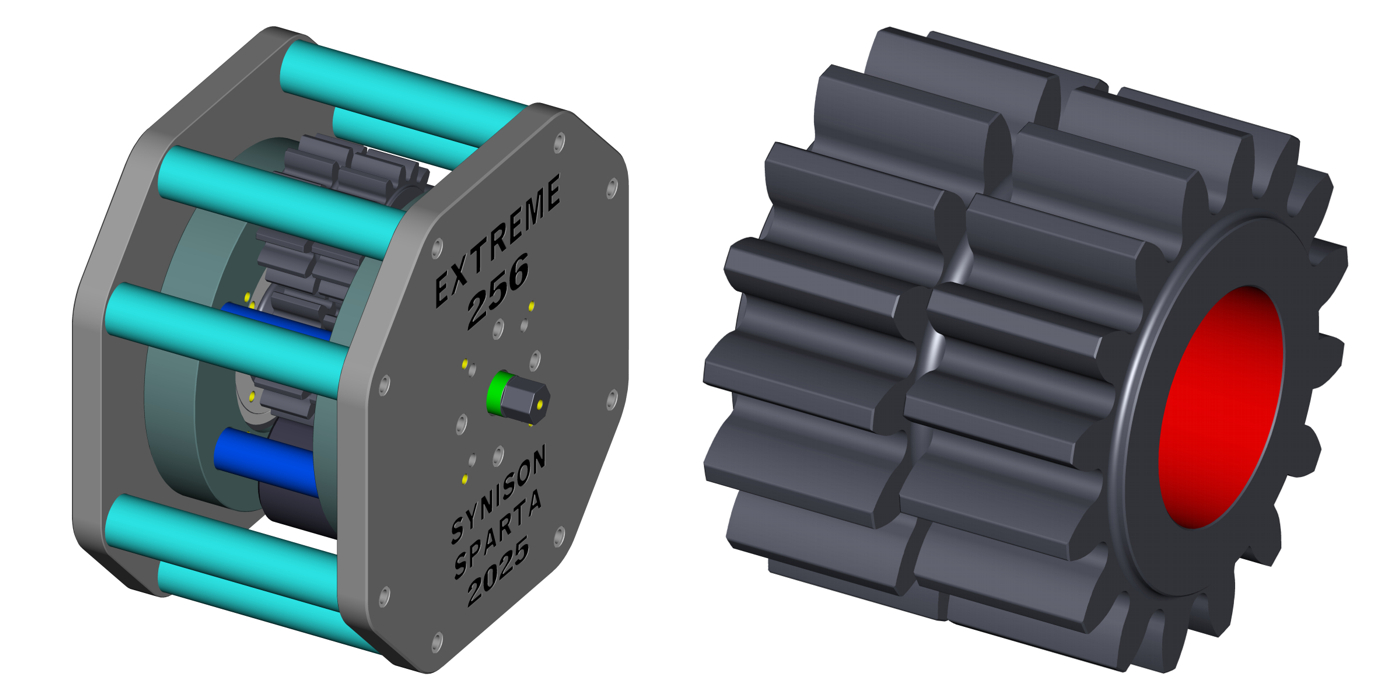

Its simplicity, characterized by only three moving parts in its basic form, contributes to high reliability and ease of maintenance.

The mechanism is noted for its "highest possible degree of efficiency" for both, speed reduction and speed increasing, a unique characteristic that makes it suitable for a wide range of applications.

Furthermore, the estimated manufacturing cost is less than 50% of prior-art mechanisms for similar purposes and requirements, offering a significant commercial advantage.

The design also enables ideal load distribution by allowing for multiple planetic units, which reduces the required tooth width and improves space utilization (volume less than 30% of that of the competition).

This technology has been high value estimated, reinforcing the scale of its potential global market impact.

Strategic Applications and Global Market Fit

Its core technical principle, as described in the patent application WO/2021/165707, is the hybridization of the differential winch and the planetary mechanism.

This innovative design results in an extremely high transmission ratio while utilizing a single only moving part between its input and output (drawing below: input/carrier, output/sun and mediator/planets).

This simplicity is a direct result of its revolutionary design, which challenges three established principles, or "dogmas," of mechanical engineering.

First, unlike conventional planetary mechanisms that rely on internal gears, the EXTREME uses only external gears, a configuration found to be more effective for achieving high transmission ratios.

Second, the design dispenses with the requirement that all gears must share the same gear module, allowing the use of different gear modules for different gear branches, one of which may be non standardized!

This provides a wider range of options for the number of teeth, enabling greater design flexibility and ratio optimization.

Third, the mechanism avoids the conventional 1:1 partial ratio in the one branch, instead setting a competitive value for the second branch that contributes to an even higher transmission ratio.

This approach is described as being "truly revolutionary" for its effect on performance.

The combination of these principles yields a mechanism with numerous strategic advantages.

Its simplicity, characterized by only three moving parts in its basic form, contributes to high reliability and ease of maintenance.

The mechanism is noted for its "highest possible degree of efficiency" for both, speed reduction and speed increasing, a unique characteristic that makes it suitable for a wide range of applications.

Furthermore, the estimated manufacturing cost is less than 50% of prior-art mechanisms for similar purposes and requirements, offering a significant commercial advantage.

The design also enables ideal load distribution by allowing for multiple planetic units, which reduces the required tooth width and improves space utilization (volume less than 30% of that of the competition).

This technology has been high value estimated, reinforcing the scale of its potential global market impact.

Strategic Applications and Global Market Fit

The technical profile of the EXTREME positions it as an ideal solution for several key sectors within the rapidly evolving global industrial landscape.

The market is not merely expanding; it is undergoing a fundamental transformation driven by the adoption of advanced manufacturing technologies, and the capabilities of the EXTREME are perfectly aligned with these trends.

The mechanism's ability to achieve extreme transmission ratios, such as even up to 1,000,000:1 as a reducer or up to 1:1,000 as an increaser, makes it particularly suitable for applications that currently rely on complex, multi-stage systems.

One prime application is as increaser in the wind energy sector, which is a major driver of the industrial gearbox global market.

The mechanism is superior to existing competitors for applications requiring drastic speed increasing, such as wind turbines, which need to convert a slow blade rotation into a high-speed generator input.

Similarly, the mechanism's high-ratio capability is well-suited for heavy-duty applications like stacker/reclaimer drives, which currently utilize planetary gearboxes with ratios ranging from 100:1 to 3,500:1.

Furthermore, the mechanism's high efficiency and compact design are critical for capitalizing on the market's shift towards sustainability and industrial automation.

The global gearbox market is increasingly prioritizing energy-efficient solutions to reduce construction and operational costs and environmental impact.

The efficiency of the EXTREME directly supports this trend.

Its compact design and high torque density also make it a strong candidate for the booming industrial automation and e-mobility markets, where precise, reliable, and space-saving components are essential.

The global industrial automation market is presenting a substantial opportunity for a product that can serve applications in robotics, automated material handling, and e-axles.

The convergence of these market trends creates an environment in which innovative, high-performance, and energy-efficient solutions are not just desirable but are actively being sought out to replace older technologies.

The design of the EXTREME is positioned to be a key enabling technology for this industrial revolution worldwide.

This tiny yet robust mechanism undoubtedly will be a fast and effective game changer in the transmission field, especially of high and very high transmission ratios.

EXTREME: ADVANTAGES IN COMPARISON WITH A CLASSIC SPEED CHANGER

The market is not merely expanding; it is undergoing a fundamental transformation driven by the adoption of advanced manufacturing technologies, and the capabilities of the EXTREME are perfectly aligned with these trends.

The mechanism's ability to achieve extreme transmission ratios, such as even up to 1,000,000:1 as a reducer or up to 1:1,000 as an increaser, makes it particularly suitable for applications that currently rely on complex, multi-stage systems.

One prime application is as increaser in the wind energy sector, which is a major driver of the industrial gearbox global market.

The mechanism is superior to existing competitors for applications requiring drastic speed increasing, such as wind turbines, which need to convert a slow blade rotation into a high-speed generator input.

Similarly, the mechanism's high-ratio capability is well-suited for heavy-duty applications like stacker/reclaimer drives, which currently utilize planetary gearboxes with ratios ranging from 100:1 to 3,500:1.

Furthermore, the mechanism's high efficiency and compact design are critical for capitalizing on the market's shift towards sustainability and industrial automation.

The global gearbox market is increasingly prioritizing energy-efficient solutions to reduce construction and operational costs and environmental impact.

The efficiency of the EXTREME directly supports this trend.

Its compact design and high torque density also make it a strong candidate for the booming industrial automation and e-mobility markets, where precise, reliable, and space-saving components are essential.

The global industrial automation market is presenting a substantial opportunity for a product that can serve applications in robotics, automated material handling, and e-axles.

The convergence of these market trends creates an environment in which innovative, high-performance, and energy-efficient solutions are not just desirable but are actively being sought out to replace older technologies.

The design of the EXTREME is positioned to be a key enabling technology for this industrial revolution worldwide.

This tiny yet robust mechanism undoubtedly will be a fast and effective game changer in the transmission field, especially of high and very high transmission ratios.

EXTREME: ADVANTAGES IN COMPARISON WITH A CLASSIC SPEED CHANGER

When introducing EX.T.R.E.ME. (https://engine.green/extreme.htm), it is usually misunderstood that its main innovative feature is that the transmission ratio it achieves is a perfect square of an integer.

In fact, however, its innovative and sharper feature is that for the equality of the distances of the axes of the 2 pairs of gears, a new parameter is introduced, the MM (MM=Maction/Mreaction), which is the ratio of the 2 generally different gear Modules used (Mreaction & Maction), one of which may not be standardized.

In this way, the number of combinations of the teeth numbers of the cooperating gears, that can compose the EX.T.R.E.ME., soars and thus this mechanism can approach very closely a given transmission ratio.

Moreover, from these combinations, the algorithm that composes the EX.T.R.E.ME. can balancedly choose the teeth numbers of the cooperating gears, resulting in an all-parameters optimized robust, impressively compact and impressively efficient mechanism.

In summary, briefly but comprehensively, the advantages of the EX.T.R.E.ME. are:

1) It can achieve almost any transmission ratio, in the sense that this will be within a range of usually ±2% around the desired transmission ratio, much closer than a 2-stage classic speed changer can.

2) Whatever the transmission ratio, the difference in the teeth numbers of the cooperating gears, of both pairs/branches, can be as small as possible and thus the contact ratio will be as large as possible.

3) In any case, it has not a single pinion, which is always the weakest link in any power transmission chain and the required strength of this problematic part determines the dimensions (thus volume and weight) of the entire mechanism; it must be noted that:

- all classic spur gearboxes have pinions, having either a few or more stages, where each stage has a small (pinion) and a large gear, and

- the vast majority of planetary systems have pinions as well, since usually the central sun is a pinion itself but also the planets cooperating with it are pinions, resulting in that their cooperation often has serious overload problems and short operational life.

4) In any case, the necessary moving parts are only 3, while their supporting machine elements (bearings, bushings, magnetic bearings, gas bearings or others) are respectively 6.

This means low manufacturing costs, the most economical operation, but also minimal friction losses during operation, therefore simple and economical cooling if required.

5) In the case where a very high transmitted torque is required, up to 5 planetary units can be used and then the exploitation of the available space of the mechanism is the greatest possible, in other words the ratio of transmitted torque to mechanism volume is the maximum possible.

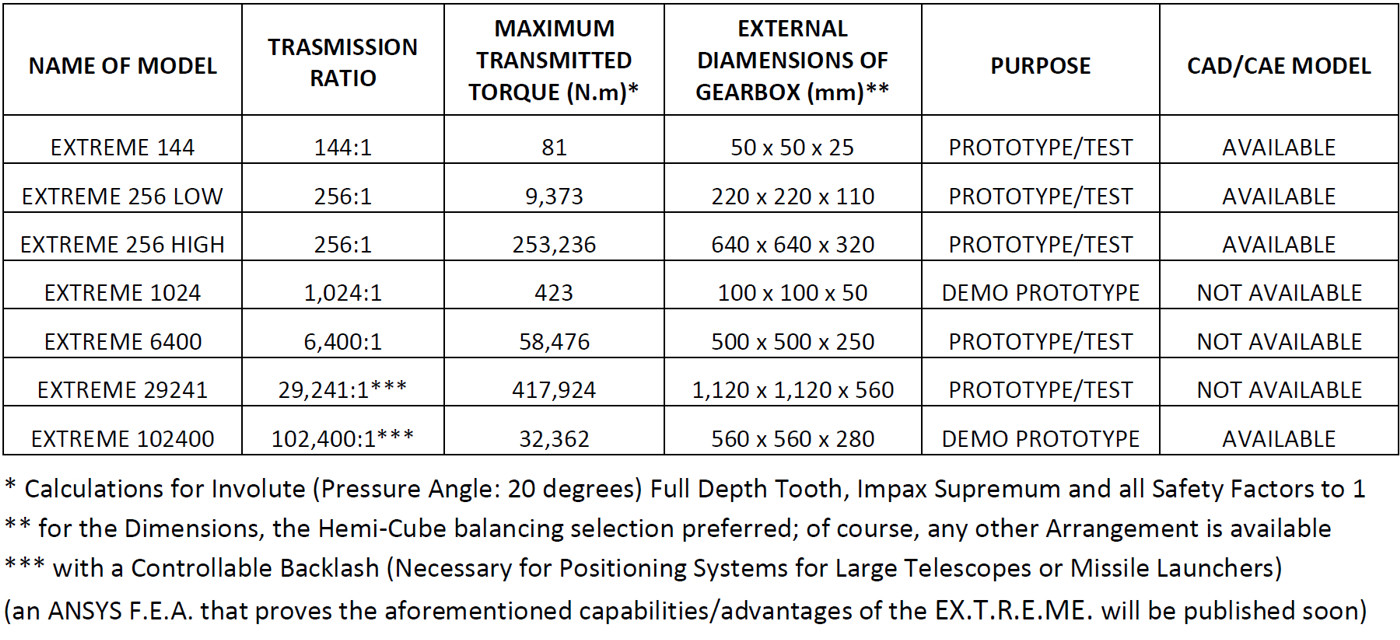

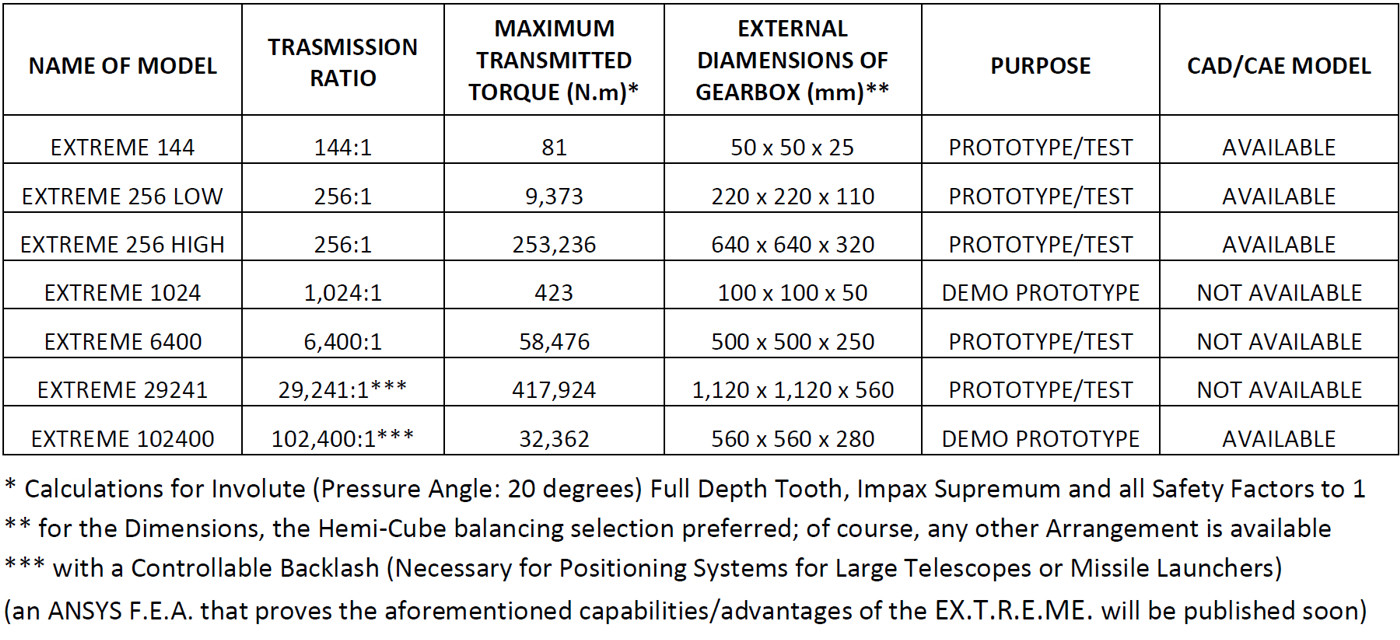

6) In the special case where the required transmission ratio is convenient or is just accepted to be the perfect square of an integer, then the EX.T.R.E.ME. has by far the smallest dimensions and therefore the lowest possible volume and weight of any similar proposal (even more than 50% less than that of the classic speed changer with the same requirements in terms of transmission ratio and torque); below is a short list of such examples:

EXTREME: A SUMMARY OF KEY BENEFITS, APPLICATIONS AND IMPACT

In fact, however, its innovative and sharper feature is that for the equality of the distances of the axes of the 2 pairs of gears, a new parameter is introduced, the MM (MM=Maction/Mreaction), which is the ratio of the 2 generally different gear Modules used (Mreaction & Maction), one of which may not be standardized.

In this way, the number of combinations of the teeth numbers of the cooperating gears, that can compose the EX.T.R.E.ME., soars and thus this mechanism can approach very closely a given transmission ratio.

Moreover, from these combinations, the algorithm that composes the EX.T.R.E.ME. can balancedly choose the teeth numbers of the cooperating gears, resulting in an all-parameters optimized robust, impressively compact and impressively efficient mechanism.

In summary, briefly but comprehensively, the advantages of the EX.T.R.E.ME. are:

1) It can achieve almost any transmission ratio, in the sense that this will be within a range of usually ±2% around the desired transmission ratio, much closer than a 2-stage classic speed changer can.

2) Whatever the transmission ratio, the difference in the teeth numbers of the cooperating gears, of both pairs/branches, can be as small as possible and thus the contact ratio will be as large as possible.

3) In any case, it has not a single pinion, which is always the weakest link in any power transmission chain and the required strength of this problematic part determines the dimensions (thus volume and weight) of the entire mechanism; it must be noted that:

- all classic spur gearboxes have pinions, having either a few or more stages, where each stage has a small (pinion) and a large gear, and

- the vast majority of planetary systems have pinions as well, since usually the central sun is a pinion itself but also the planets cooperating with it are pinions, resulting in that their cooperation often has serious overload problems and short operational life.

4) In any case, the necessary moving parts are only 3, while their supporting machine elements (bearings, bushings, magnetic bearings, gas bearings or others) are respectively 6.

This means low manufacturing costs, the most economical operation, but also minimal friction losses during operation, therefore simple and economical cooling if required.

5) In the case where a very high transmitted torque is required, up to 5 planetary units can be used and then the exploitation of the available space of the mechanism is the greatest possible, in other words the ratio of transmitted torque to mechanism volume is the maximum possible.

6) In the special case where the required transmission ratio is convenient or is just accepted to be the perfect square of an integer, then the EX.T.R.E.ME. has by far the smallest dimensions and therefore the lowest possible volume and weight of any similar proposal (even more than 50% less than that of the classic speed changer with the same requirements in terms of transmission ratio and torque); below is a short list of such examples:

EXTREME: A SUMMARY OF KEY BENEFITS, APPLICATIONS AND IMPACT

KEY BENEFITS

Backlash reduction: by design avoids multi-stage accumulation; moreover is easy to render this backlash absolutely ZERO.

Efficiency: spur-gear (straight or helical) efficiency, up to +25% in comparison with conventional solutions.

Cost reduction: up to -50% in construction & maintenance.

Compactness: less than 50% of the volume and weight of the ones of the competition.

Dual function: usable as reducer (motors > precision drives) or increaser (low-speed devices > useful power output).

APPLICATIONS

Astronomy & Space: telescope mounts, radio telescopes, spacecraft pointing systems.

Energy: wind turbines, Stirling engines and other slow work-producing machines (as increasers driving generators), FLYWHEEL STORAGE (Mechanical Battery).

Robotics & Industry: extreme precision positioning, solar panel trackers.

Transportation: compact, powerful EV drive units, UAVs/drones.

IMPACT

Achieves ratios current reducers reach with tens of moving parts, using only three.

As an increaser, reaches ratios unattainable by competitors.

Opens entirely new design possibilities in precision mechanics.

this site is property of SYN ISON and is under construction

M O R E (complete description, drawings, claims etc) as PDF

M O R E (complete description, drawings, claims etc) at WIPO

This MECHANISM has already a US Granted Patent

and Pending Patent Applications in other countries of industrial interest,

while -until the next phase of publication- this website is under construction.

So, if you want more information you can download the Deck of our Team (Company under creation):

a brief presentation though focused on some specific applications

or

a relatively larger presentation

or

write directly to the e-mail address:

Info for the REDUCEST PROJECT

Backlash reduction: by design avoids multi-stage accumulation; moreover is easy to render this backlash absolutely ZERO.

Efficiency: spur-gear (straight or helical) efficiency, up to +25% in comparison with conventional solutions.

Cost reduction: up to -50% in construction & maintenance.

Compactness: less than 50% of the volume and weight of the ones of the competition.

Dual function: usable as reducer (motors > precision drives) or increaser (low-speed devices > useful power output).

APPLICATIONS

Astronomy & Space: telescope mounts, radio telescopes, spacecraft pointing systems.

Energy: wind turbines, Stirling engines and other slow work-producing machines (as increasers driving generators), FLYWHEEL STORAGE (Mechanical Battery).

Robotics & Industry: extreme precision positioning, solar panel trackers.

Transportation: compact, powerful EV drive units, UAVs/drones.

IMPACT

Achieves ratios current reducers reach with tens of moving parts, using only three.

As an increaser, reaches ratios unattainable by competitors.

Opens entirely new design possibilities in precision mechanics.

this site is property of SYN ISON and is under construction

M O R E (complete description, drawings, claims etc) as PDF

M O R E (complete description, drawings, claims etc) at WIPO

This MECHANISM has already a US Granted Patent

and Pending Patent Applications in other countries of industrial interest,

while -until the next phase of publication- this website is under construction.

So, if you want more information you can download the Deck of our Team (Company under creation):

a brief presentation though focused on some specific applications

or

a relatively larger presentation

or

write directly to the e-mail address:

Info for the REDUCEST PROJECT